CONNECTED magazine n°4

堅固的高速連接器在軍工應用中興起

過去二十年里,在技術進步、新興威脅以及日益增長的實時數據傳輸需求的推動下,軍工領域經歷了快速變革。從以網絡中心戰和人工智能監控,到自動駕駛車輛和先進的網絡防御系統,該行業比以往任何時候都更加依賴安全且高速的連接。 這些創新要求連接解決方案不僅堅固耐用、高可靠,還要具備越來越快的傳輸速度,能夠在最惡劣的環境下工作,同時確保數據的無縫傳輸。

CONNECTED 16: Discover the 75th anniversary edition of our CONNECTED magazine

Three quarters of a century are well worth a special edition! We have delved into our archives to be able to tell you everything about the history of the LEMO Group: how it all started in a rented 50m2 workshop; how the founder’s passion for photography brought about the invention of the Push-Pull system; how LEMO Group companies invented solutions to equip your most demanding applications and muc

CONNECTED 17: the new edition of our hi-tech magazine is out!

Our special feature will focus on robotic surgery through an interview with a surgeon and the portrait of two major players in this emerging market sector. You can also discover the world’s largest telescope, Europe’s first Hyperloop test tube and a solar boat with a rather unusual design. We will take you to the home of the iconic Nagra brand to listen to their first and extraordinary hi-fi turnt

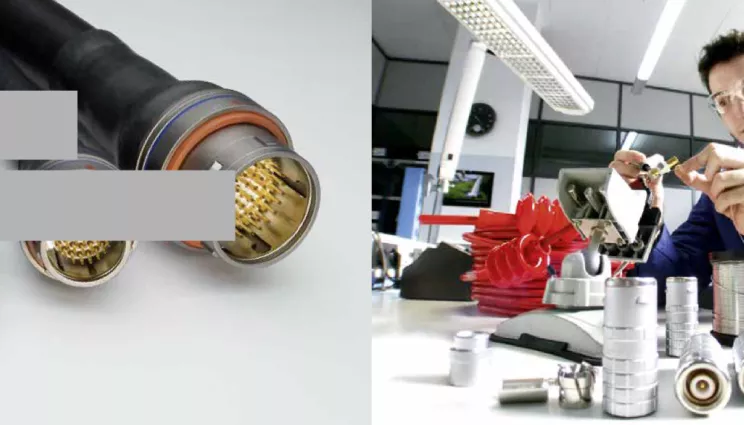

Beyond connectors

LEMO’s long experience and solid expertise in the field of connector and cable assembly has now beenextended by offering complete interconnection solutions.

Sculpteo: the success of a factory in the cloud

"There began to be a lot of talk about 3D software,3D objects and 3D printing in 2009” explains Clément Moreau, co-founder of Sculpteo. “For us, it was a new revolution in the history of industry. So we started to get ready for when the big wave would arrive…”

Printing an exact copy of the patient

In the printer are two polymer materials owned by 3D Systems: the material which will “hold” the finest elements and the building material itself. Once it's printing, the machine super- poses – one by one – layers 32 microns deep.